Heat exchangers are the circulatory system of modern industry, crucial for processes ranging from power generation to chemical manufacturing. When these vital components suffer from fouling—the accumulation of deposits on the tube walls—the entire operation is jeopardized. For facility managers and maintenance professionals, dealing with fouled heat exchangers is a constant battle against inefficiency and unexpected downtime.

The Real Cost of Fouling: When Efficiency Dies

Fouling isn't just a dirty tube; it's a critical technical issue. Deposits—such as hard scale, silt, coked materials, and aggressive polymers—create an insulating layer inside the tubes. This directly leads to a significant reduction in the heat transfer rate.

In technical terms, the Heat Transfer Coefficient ($U$) plummets, forcing the system to consume more energy to achieve the desired temperature output. If left untreated, severe fouling can cause catastrophic pressure drops, overheating, and ultimately, the forced shutdown of the entire unit. The financial impact of lost production and excessive energy consumption is enormous.

PressureJet Hydro Jetting: The Gold Standard Restoration

While conventional cleaning methods like drilling or chemical baths exist, they often fail to provide a complete, long-term solution. Mechanical drilling can scratch and damage soft metal tubes, and chemicals pose significant environmental hazards while struggling to penetrate heavily cured deposits.

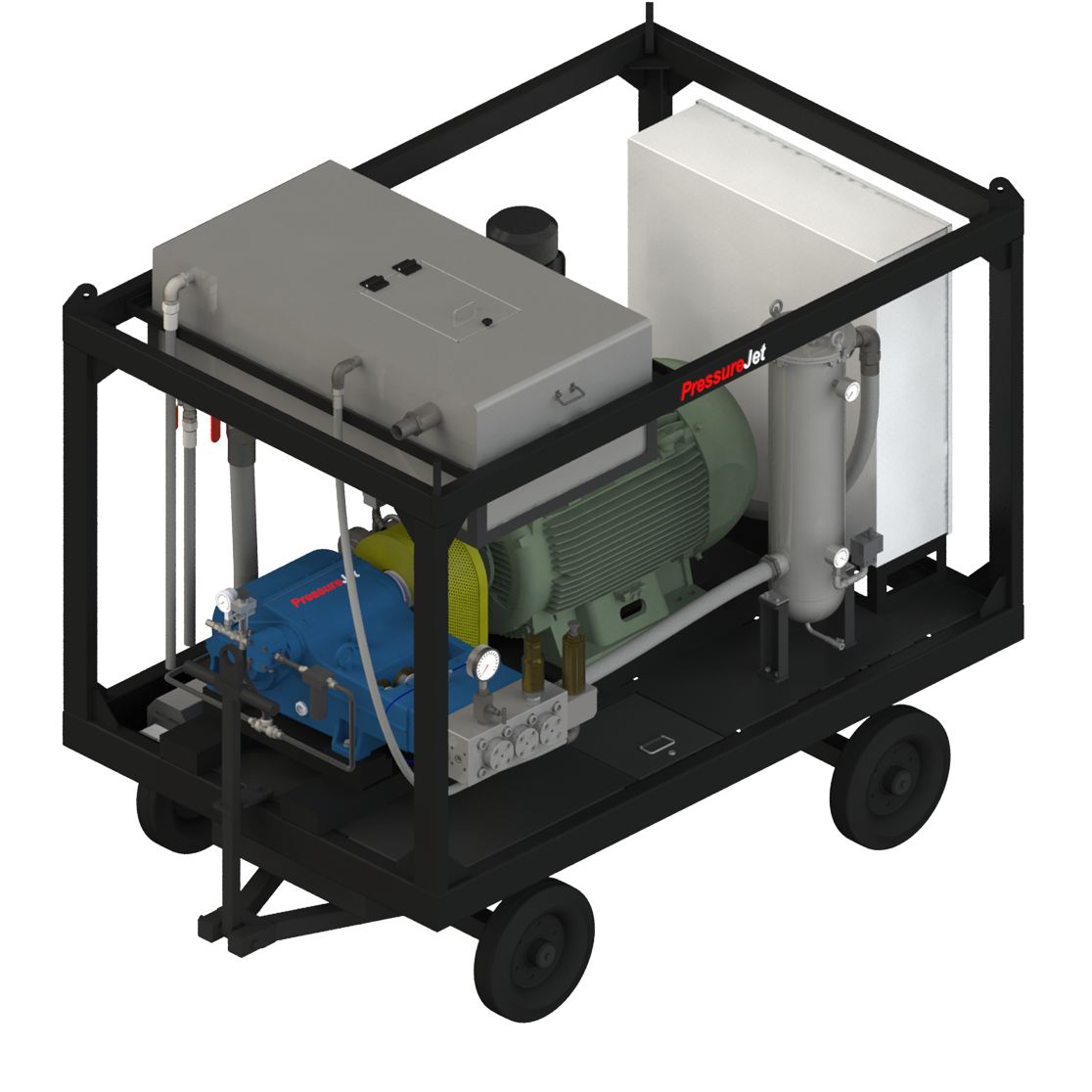

This is where high-pressure Hydro Jetting—powered by a robust PressureJet Water Jet Cleaning Machine—becomes the undisputed superior restoration technique.

How PressureJet Systems Achieve a 'Like-New' Clean:

- Ultra High Pressure (UHP) Power: Our industrial-grade Triplex Plunger Pumps generate extreme water pressure, often exceeding 10,000 PSI, which is sufficient to fracture and remove the hardest scale and toughest polymers.

- Specialized Tooling: Operators utilize specialized accessories, such as rigid or flexible lances equipped with multi-directional, aggressive nozzles. These tools are specifically designed to navigate the tube interior and scour the entire internal circumference.

- Total Scour: The high-velocity water jet blasts away every layer of internal deposit, effectively restoring the tube's original, smooth interior diameter. This level of clean is impossible to achieve with standard mechanical or chemical methods.

Why PressureJet Is the Smart Investment

Choosing a high-pressure system from PressureJet provides tangible, measurable benefits that directly impact your bottom line and operational stability:

- Maximum Efficiency Restoration: Complete removal of the insulating fouling layer maximizes the heat transfer coefficient, leading to significant energy savings and optimized operational performance that lasts longer.

- Zero Chemical Risk: Our process uses only water. This eliminates the storage, handling, and disposal risks associated with aggressive chemical solvents, ensuring a safer workplace and environmental compliance.

- Reduced Downtime: Hydro jetting is a rapid, powerful process that drastically cuts the time required for maintenance, getting your critical heat exchangers back online faster than any alternative.

- Extended Asset Life: The water jet cleans without scratching or eroding the tube material, preserving the structural integrity and extending the overall lifespan of your expensive heat exchanger bundle.

Equip Your Maintenance Team with the Best

When the circulation system of your industry is at stake, you need a solution built for reliability and results. PressureJet Hydro Jetting Machines are engineered for extreme durability and precision.

Ready to maximize your heat exchanger efficiency and minimize unscheduled shutdowns? Contact PressureJet today to discuss configuring the ideal high-pressure system for your facility.