Customer:

Confidential (Large-Scale Petrochemical Manufacturer)

Project Category:

Petrochemical and Refining

Customer Requirement:

The client required six heavy-duty, ultra high-pressure water jet cleaning systems capable of continuous, 24/7 operation. Key technical requirements included: High Pressure: Must achieve a minimum working pressure of 1000 Bar (14,500 PSI) to effectively remove coked material and hard polymer scale. Mobility: Machines needed to be skid-mounted for stable, stationary use within their respective facilities. Safety & Automation: Integration of enhanced safety features, including remote control options for semi-automatic tube cleaning operations. Standardization: All six units must be identical in specifications to simplify training, maintenance, and spare parts inventory.

Project Result:

The successful deployment of the six Hydro Jetting Machines enabled the client to achieve several critical operational improvements: Centralized Maintenance: Standardization simplified maintenance procedures and spare parts management across all six plant locations. Efficiency Spike: The high-pressure systems drastically reduced the time required for cleaning heat exchanger tube bundles, leading to a measured average decrease in maintenance downtime of 35% across the integrated facilities. Performance Reliability: The robust design ensured sustained operation, allowing the client to move maintenance schedules from reactive shutdowns to predictive, planned operations, thereby maximizing annual throughput.

What we did:

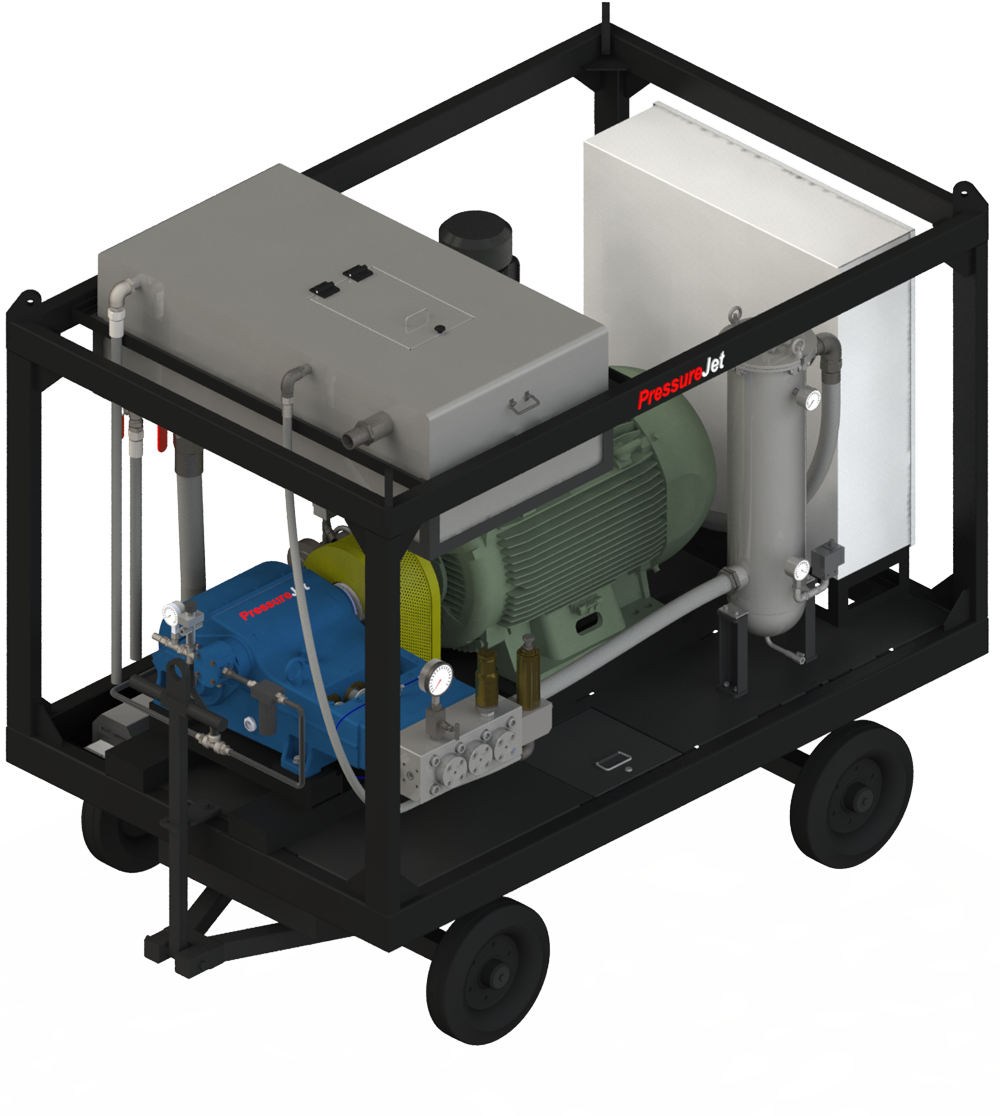

PressureJet designed, manufactured, and delivered six identical high-pressure units, including: Custom Engineering: Each unit was built around a specialized Triplex Plunger Pump rated for 1000 Bar operation, driven by a heavy-duty industrial electric motor. System Integration: Each skid included a multi-stage filtration system, pressure regulating valves, and a sophisticated control panel with emergency stop features. Accessory Package: We supplied a full inventory of accessories for each machine, including rigid lances, flexible lances, and specialized rotating Raptor nozzles optimized for internal tube cleaning. Training & Commissioning: Our technical team provided on-site commissioning and comprehensive training to the client's maintenance personnel on operation, safety protocols, and preventive maintenance for all six deployed machines.

Project Description

This case study details the successful execution and delivery of a significant order for six high-specification PressureJet Hydro Jetting Machines. The project aimed to standardize the client's industrial cleaning fleet across multiple production units, ensuring uniform performance, maximum efficiency, and reduced maintenance downtime for critical assets like heat exchangers and pipelines.

Project Budget:

20000000

Completion Date:

2025-12-01T00:00:00